COATING

Sintered NdFeB magnets are very sensitive to corrosion and to maximize corrosion stability other alloy components such as Co are often added. On the other hand, this type of corrosion protection is often insufficient. NdFeB magnets need additional protection against corrosion.

There are two types of protection:

- Short-term protection: Surface passivation

- Long-term-protection: Coating

Surface passivation

Passivation improves the storage time of the magnets and protects the magnets from corrosion during transport. All Yunsheng magnets are supplied with a passivation coating, which serves as protection against moisture. The thickness of the passivation coating can be 200 – 600 nm. The storage time for unprotected magnets is about 7 days. According to the thickness of the coating, passivated magnets have a storage time of about 3-6 months at a temperature of 22° C and humidity of no more than 60 %.

Coating

Complete protection for a magnet against corrosion and various surrounding media such as for example oils or corrosive substances can only be ensured by using an application-specific coating.

As a general rule, the coating for NdFeB magnets should meet the following requirements:

- Minimal coating thickness (to minimize the air gap)

- Good adhesion of the coating material

- Not sensitive to changing climate influence; good temperature stability

High degree of production reliability during the coating process - Efficiency

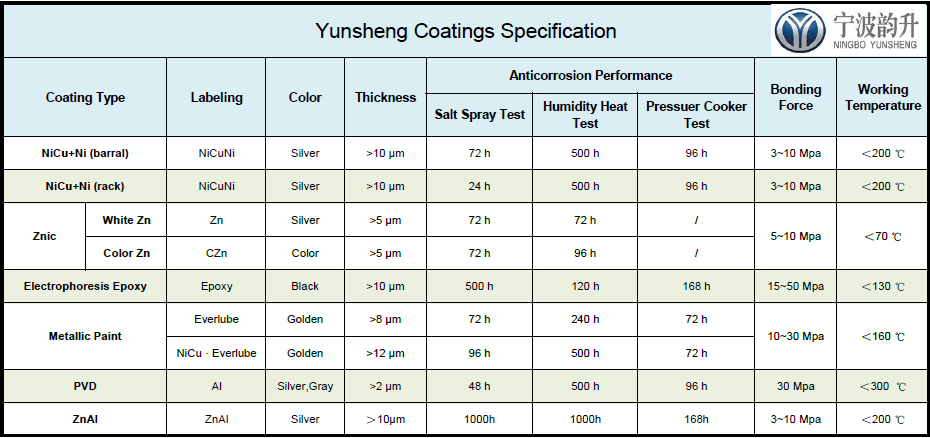

Coating table with an overview of the different types of coating frequently used by Yunsheng: