GBD – GRAIN BOUNDARY DIFFUSION

GBD magnets are an environmentally friendly solution.

One of the main topics in world-wide permanent magnet research is the reduction of HRE, without thereby impairing the performance of NdFeB permanent magnets, but rather to improve it further. A very promising approach to achieving this aim is the so-called grain boundary diffusion process, known as the GBD process.

In this recently introduced production process, it is possible clearly to increase the intrinsic coercive field strength HcJ of NdFeB magnets:

The demagnetization curves of an NdFeB magnet before the GBD process (red curve) and after the GBD process (black curve) at 120° C and 150° C. It is important to note here that the GBD process has a negligible influence on the residual polarization Br.

Here, the increase of the coercive field strength HcJ depends on the thickness of the magnet. The thinner the magnet, the better the coercive field strength HcJ. Here you can find Graph 1.

If HRE is used efficiently, the reduction of the magnetic residue can be practically disregarded. Here you can find Graph 2.

GBD – PVD

There are many options for carrying out the GBD process.

Yunsheng uses the following two methods:

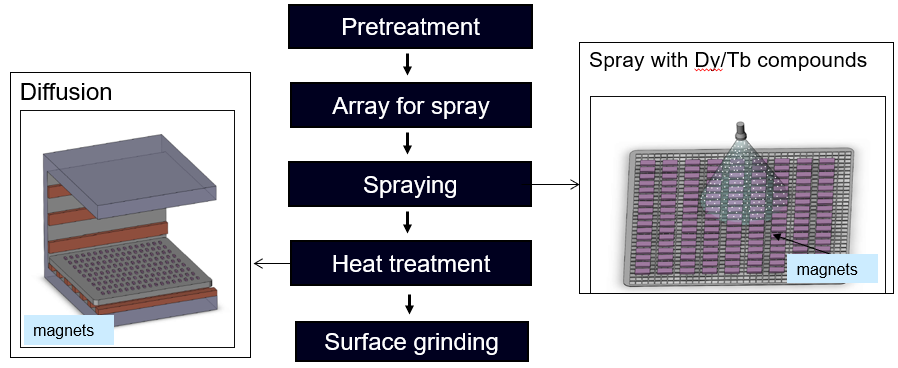

Spray method

Physical Vapor Deposition – PVD method

The spray manufacturing process for GBD sintered NfFeB magnets

In the GBD process, sintered permanent magnets are coated with a thin layer of heavy rare earth metal (HRE) and then undergo a special heat treatment. During the heat treatment, material with an HRE content diffuses along the grain boundaries into the interior of the magnet. This means that the NdFeB grains are surrounded by an HRE-rich shell.

Here you can find the GBD alloys and here the demagnetization curves.